North Stanmore Extraction & Processing

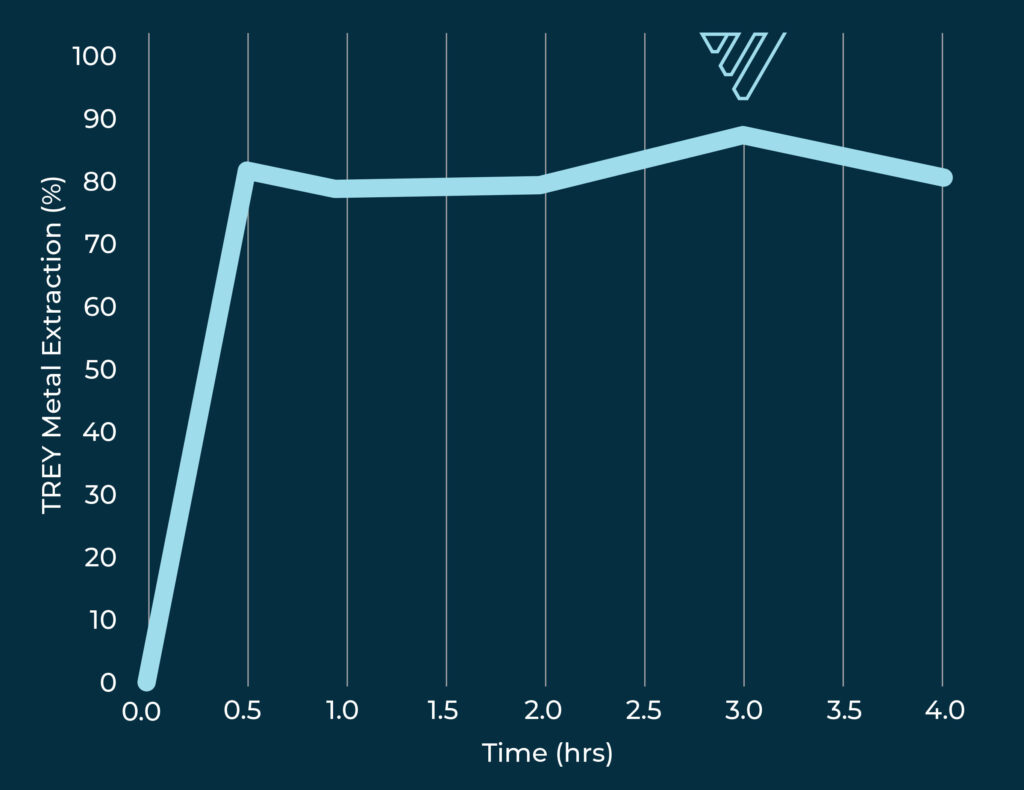

Kinetic leach results show a major reduction in leach time for the North Stanmore Project with ~80% of rare earths leached in 30 minutes compared to the 4-hour assumption used in the Scoping Study. The rapid leach kinetics confirm a clear pathway to a smaller leach circuit, lower reagent consumption and improved process efficiency.

- Breakthrough metallurgical results ~80% of rare earths leached within 30 minutes, compared to previous 4 hour leach results

- Up to 8 times shorter leach times which is expected to lower both CAPEX and OPEX through smaller leach circuit

- Rapid kinetics validate North Stanmore’s unique mineralogy and processing advantage over global peers

- Engineering and metallurgy programs underway to capture the upside and integrate results into the PFS

- Rapid extraction of valuable and defense strategic heavy rare earth elements Dysprosium (Dy), Terbium (Tb) and Yttrium (Y)

- Victory’s flow sheet is set to benefit from the large ratios of Yttrium with North Stanmore hosting globally significant volumes of Y2O3 in-situ, with current prices surging over 4,400% to US$270 per kg1

- North Stanmore continues to demonstrate that it is one of the largest, most technically advanced heavy rare earth clay hosted projects globally outside of China

- Further testing at a 1ti minute interval underway

Industry peers require ~24 hour leach times. The Scoping Study CAPEX was based on a 4 hour leach cycle, meaning there is significant scope for both CAPEX and OPEX reductions as the process is optimised.

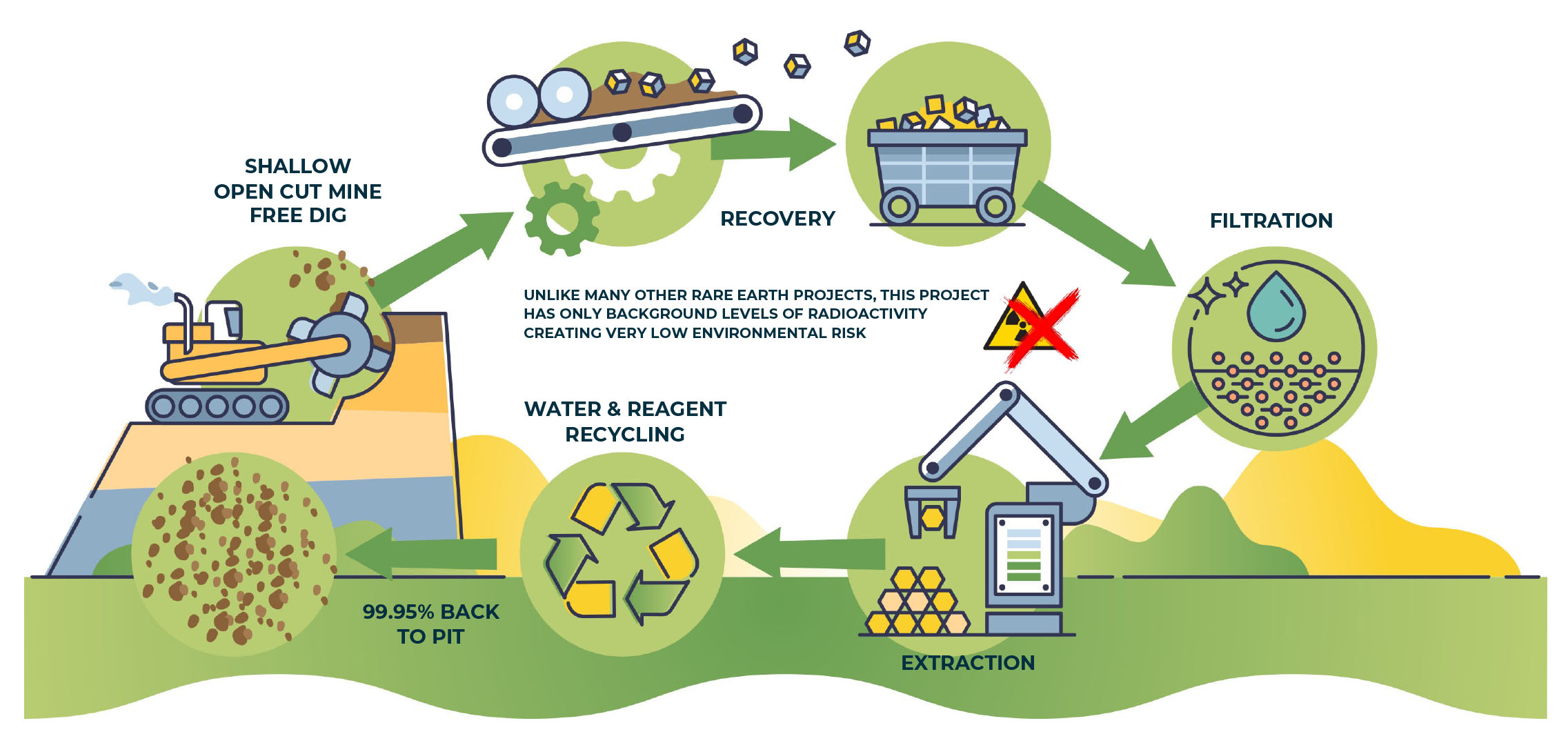

Victory is also the only clay hosted project in Australia to have produced a 94% high-purity Mixed Rare Earth Oxide (MREO), as well as Mixed Rare Earth Carbonate and Oxalate products, providing flexibility for downstream customers. Importantly, these products contain very low concentrations of deleterious elements like Al, Mg and Fe.

The process involves minimal radioactivity as levels of uranium and thorium in the ore are similar to concentrations in average continental crust. Waste stream opportunities to recycle reagents provide the potential to produce valuable by-products such as Magnesium oxide (MgO).